How Accurate is an Analytical Balance? Understanding Uncertainty

2026 Feb 9th

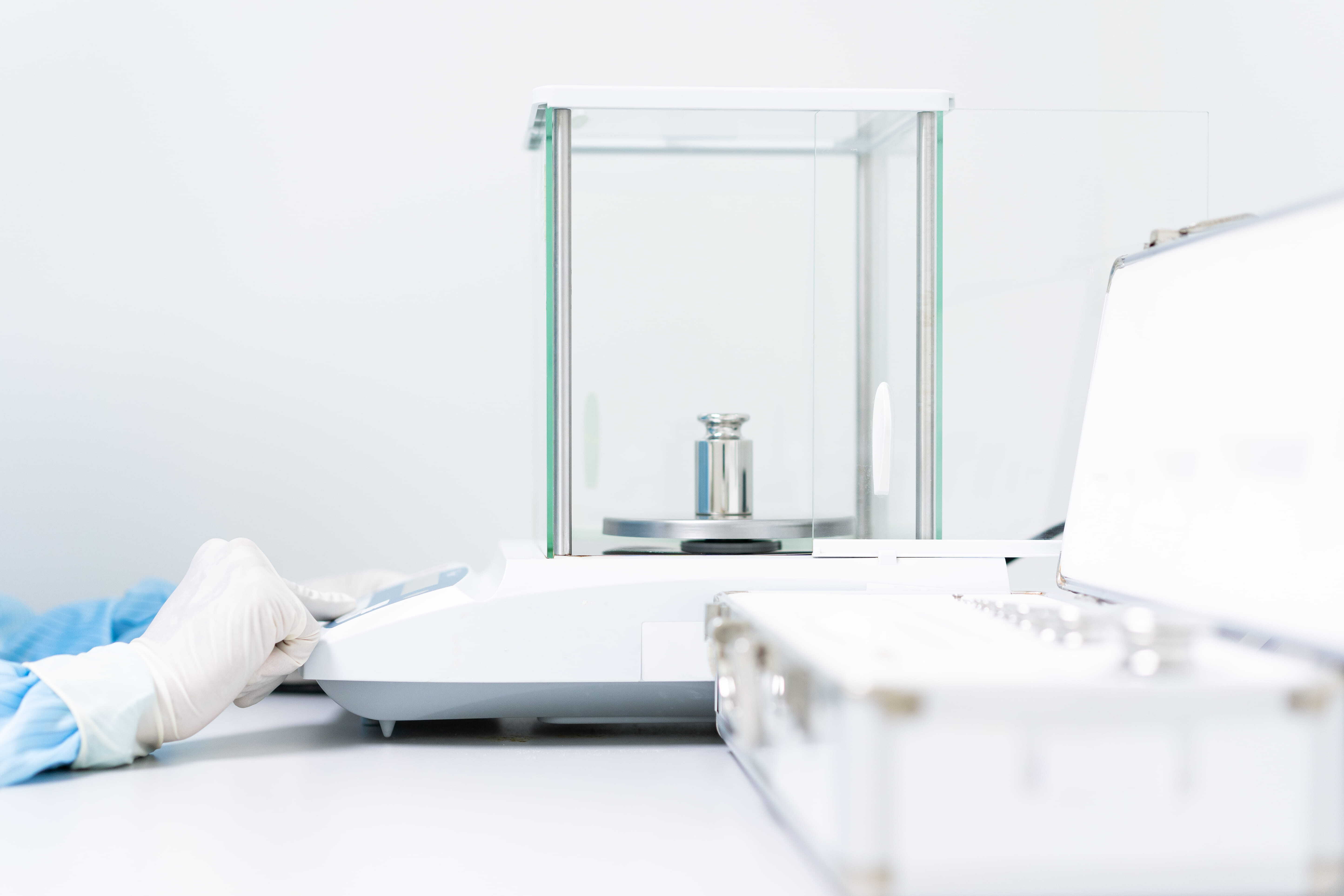

The accuracy of a laboratory's analytical balances and weighing equipment depends on numerous quantifiable factors, such as operator handling and environmental variations. A key factor in understanding balances is to understand how uncertainty plays a vital role in reliable measurements.

This article explains the importance of operators maintaining best practices and understanding the difference between accuracy and uncertainty. The aim is to support you in yielding accurate and dependable laboratory results.

The Importance of the Accuracy of Laboratory Weighing & Why it Matters

Accuracy across laboratory weighing remains a fundamental aspect in the scientific industry. Ensuring the accuracy of analytical balances and weighing equipment is a vital way to support reliable results, uphold safety standards, and strengthen scientific credibility.

What Determines Accuracy?

Accuracy is the closest measurement of mass to the accepted value. For example, high accuracy is the measurement that is close to the true value.

In relation to analytical balances, accuracy is dependent on calibration, balance design, and linearity.

Balance Readability & Calibration

Balance readability is the smallest unit of mass that a balance can detect and display, often signified by ‘d’. The higher the readability, the finer the solution.

Balance calibration is the process of verifying and adjusting the internal mechanism using certified standard weights. This calibration prevents drifts and supports valid measurements; this is particularly important for the chemical and pharmaceutical sectors.

Environmental & Operator Influences

Environmental and operator influences can affect the accuracy of analytical balances, as balances and weights are highly sensitive. To ensure that there are limited impacts to analytical balances and equipment, operators should consider:

- Air currents: Drafts from windows or foot traffic can cause the weighing pan to move, resulting in unstable readings. Often, analytical balances will have a draft shield to mitigate effects from air currents.

- Improper sample handling: Using bare hands leaves excess heat, moisture, and oils on the pan, which impacts measurements. To eradicate this risk, operators should always wear gloves.

- Vibrations: From foot traffic to alternative equipment, vibrations can impact measurements. Place analytical balances and equipment on stable, anti-vibration tables to minimize vibrational impact.

- Poor housekeeping: Keep analytical balances and weighing equipment clean to prevent dust and residue from affecting measurements.

- Humidity: Both low and high humidity can impact moisture changes and static electricity buildup. Using dehumidifying systems and controlled ventilation can limit humidity impacts.

- Incorrect calibration: Regular and proper calibration mitigates systematic errors. Recalibrate or readjust balances whenever environmental conditions change significantly.

- Electric charges & magnetic fields: Strong electric and static charges from nearby equipment can interfere with the balance's internal mechanics.

Accuracy vs. Uncertainty

What is the uncertainty of an analytical balance? Uncertainty is the quantifiable measurement of the range of values within which the true mass is considered to fall. For example, uncertainty is the confidence in the measurement, not the accuracy.

In relation to balances, uncertainty includes balance readability, calibration uncertainty, environmental factors, and the operator's technique. Together, both accuracy and uncertainty work across analytical balances. For results that you can trust, operators should aim for high accuracy and low uncertainty.

If accuracy and uncertainty work together, what are the key differences, and why is uncertainty critical?

Key Differences

From its definition to reduction, the key differences across accuracy and uncertainty are as follows:

- Definition: Accuracy is the closeness to the true value; uncertainty is the range of possible values.

- Focus: Accuracy is the correctness; uncertainty is confidence.

- Expressed as: Accuracy is expressed as a single value, or error; uncertainty is expressed as a ± value or interval.

- Determined by: Accuracy is determined by calibration & bias; all error sources determine uncertainty.

- Can be reduced by: Operators can improve accuracy through better calibration, while improved controls and techniques reduce uncertainty.

Why Uncertainty is Critical

There are various reasons why uncertainty is critical for laboratory results. We have compiled a list of why:

- Ensures reliability: Uncertain measurements allow laboratories to understand how a result may vary from the true value. This comparison establishes reference values and standards.

- Aids critical decision making: Understanding uncertainty helps assess potential risks and determine product tolerances. Without uncertainty, a result may appear to be more precise than it is.

- Guides process improvement: The laboratory can reduce variations, such as environmental factors and operator techniques, leading to more accurate and dependable results.

Operators must understand the importance of measurements and uncertainty, and actively manage uncertainty to minimize it.

Managing Uncertainty

Common Sources of Error

There are two types of common errors across uncertainty, this includes random and systematic errors.

Random errors can cause unpredictable changes and affect the precision of results. These random errors are a result of unpredictable factors such as instrument noise, physical and environmental variations.

Identifiable biases in the setup and procedure stage cause systematic errors, which primarily affect accuracy. These identifiable biases include flawed procedure setup, alignment errors, instrument errors, and consistent environmental factors.

Mitigating random and systematic errors is easily upheld by consistently following best practices.

Best Practices to Reduce Uncertainty

Operators and laboratory personnel can receive the most accurate results by following best practices. We have outlined seven best practices that reduce uncertainty.

- Choose the right laboratory analytical balance and ensure that it is calibrated

- Control the weighing environment

- Use the correct weighing technique

- Minimize the static electricity and temperature effects, such as humidity and air flow

- Use the appropriate containers and equipment

- Perform routine checks and maintenance

- Document and follow standard procedures

Are you ready to find the balance and analytical scales that suit your laboratory?

Practical Takeaways for Reliable Weighing

The accuracy of an analytical balance depends on numerous quantifiable factors, and understanding uncertainty is crucial to ensuring dependable laboratory results.

Are you ready to find the balance that works best in your laboratory? You can reach out to our expert team and discover our entire range of analytical balances and scales.